I struggled with the laser to create this “easy” project.

I struggled with the laser to create this “easy” project.

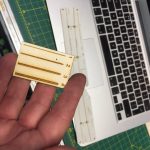

The aim is to create a template for soldering a train set “catenaire”. This is made of brass parts that require precise soldering. The wood template allows for the parts to be put inside small track before being soldered together.

We started creating an Autocad Inventor file and exporting the “faces” as usual. Unfortunately this would create some faulty files which the laser could not understand. Some parts needed vector cutting and others engraving. The engraving could not be done because the DXF file created by autocad inventor was creating conflicts of overlaps and non-closed loops.

I initially discounted the use of a JPG because of the requirement for precise sizing of various part on the template in mm or sub-mm.

initially discounted the use of a JPG because of the requirement for precise sizing of various part on the template in mm or sub-mm.

After many trials and errors, including the creation of a file on the CNC router X-Carve. I just reverted to the JPG method and sized the file inside the lasercut software. Although it was not as “elegant”, it got the part done which sometimes is the only thing that really counts.