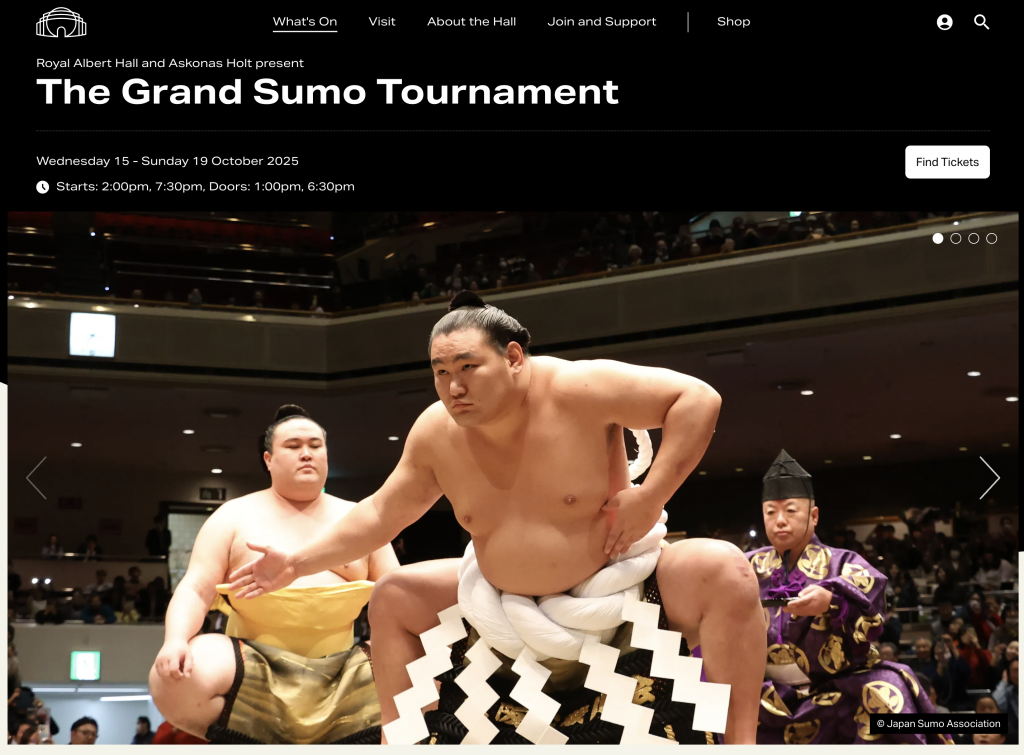

Made some gifts for clients that James is taking to a Sumo competition.

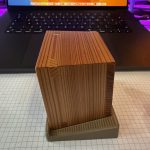

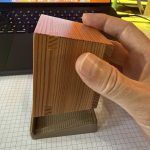

The cups were ordered from Japan, and I laser-engraved our logo and the customer’s logos.

I had to make a 3D printed holder to ensure that the face I was engraving was horizontal during the process.

It is always a lot more complicated than it seems at first sight.

- The customer logos were in different formats and colours, and had to be converted to vector files

- The file needed reference points to ensure all logos would fit on the available space and be easily calibrated once at the laser.

- The cups were not square or flat…

- A couple of cups were substantially undersized

- Calibrating the laser to have a repeatable engraving

- Cleaning up the laser dust on the nicely finished wood

- Putting back the cups inside their boxes without damaging the thin paper wraps of various sizes…

- Labelling the finished products for each client

I only had one “spare” to play with for the laser settings, etc, as usual, it was all very tight in deadlines….

I hope the clients enjoy the evening and the gifts!