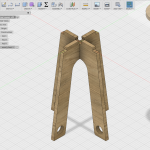

My first true design of something for the Xcarve. There has been a few mistakes along the way and still have not managed to get a final product from the machine yet…

My first true design of something for the Xcarve. There has been a few mistakes along the way and still have not managed to get a final product from the machine yet…

I am close.

The router bits, feeds and speeds are something that you must acquire and work to make test cuts etc…until you get a clean cut that does not destroy the router bit or the machine.

I have had a few crashes and also made some part of the wrong size.

I am getting close.

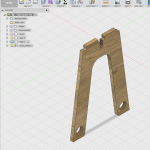

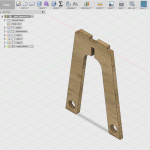

I could have made this simple stool using traditional techniques in a lot less time but I want to be able to get to a complete project where I know, I could simply put a large sheet of wood and press “Go” on the computer and it would cut all the parts needed to make this simple stool.

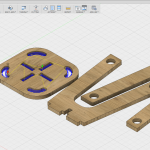

I designed it in Fusion 360, then created all the tool paths for the X-Carve in the Cam environment.

I am now using a Dewalt router, which is better than the previous Bosch Colt for which I destroyed the collet. I re-built the X-Axis as well to give it more rigidity when I installed the new X-Controller.

Wood is 18mm thick

Router bit : 10mm

Cut depth :3mm

Router Speed : 16000 rpm (dial setting 1)

Feed : 600mm/min (500mm/min works as well with less heat generated in the router bit)

Plunge : 150mm/min

No lead-ins or lead-outs.