Made a complete project with my XCarve. It all started with a friend who was trying to repair a second-hand child bicycle trainer.

Made a complete project with my XCarve. It all started with a friend who was trying to repair a second-hand child bicycle trainer.

The handlebar was broken and glue was never going to work.

The part is not very complicated but needed some smooth curves and a recess for the connection to the steering mechanism.

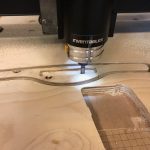

I created the fusion 360 3D model, then created a CAM setup, then posted all this to several G-Code files on my home network, [one for the pocket and the holes, one for the contour] then went to the garage and ran the G-Code on my X-Carve with a 10mm router bit at 16.000RPM, 3mm cut depth, 600mm/min feed.

It all worked perfectly ! for once…No broken bits, No burning or parts, No flying wood parts in the garage…

My friends were very happy and the fit is simply perfect.